+36 30 451 03 92

ferpol@ferpol.hu

This sewer fitting is the reliable connection

at the heart of your drainage system

Our ISO-certified PVC-U fittings are specifically designed for use with concrete manhole base elements and are designed to fit perfectly into stormwater and wastewater sewer systems.

With 20 years of experience, continuous stock, and recognition from multinational partners, we deliver quickly, reliably, and flexibly.

Click the button to view key product benefits and submit your desired order quantity.

They already order from us:

Don’t let the fitting or its supplier be the weak link in your project

Tight construction schedules leave no room for errors. A poor fit, delayed delivery, or unexpected quality issue can halt the entire project Here are the most common issues procurement and technical managers face in the sewer fitting market:

What happens if nothing

changes?

Imagine this scenario:

Everything is ready. The manholes are queued

for production, deadlines are tight, and the client

is pushing.

But the fittings haven’t arrived. The supplier is unreachable. Deadlines slip. Contractors get frustrated. The client starts talking to someone else.

When the fittings finally arrive, the first one doesn’t fit. The outer surface is too smooth: the concrete won’t bond.

You have to rework everything.

Extra labor. Extra cost. And a loss of reputation

no one wants to own.

A few weeks later, a new project starts. The client needs a supplier, but this time, it’s not you.

Click to reach our quote request form and submit your needs.

What if the seal is missing but the

concrete is already set?

Képzelje el ezt a forgatókönyvet…

It started as a routine task. The fitting was installed, the team moved fast, and the manhole was sealed.

The next day, during inspection, the issue appears: one of the installed fittings is missing its gasket. No one noticed. Not in storage, not during installation.

The concrete has already hardened.

Now the project is delayed. All because of one small, overlooked part.

You shouldn’t have to adapt to the fitting;

it should adapt to you!

If you’ve had to cut, seal, fix, or rework too many times, you know what we mean.

A fitting that’s slightly too long or short. A missing gasket. A day lost.

A bad product isn’t just annoying; it costs money.

Click the button to get closer to a real solution.

The Ferpol PVC-U sewer fitting isn’t just an

accessory. It’s the foundation you can build on.

The product adapts to your needs as follows:

*ISO EN 1401 certification ensures that the PVC-U fitting is dimensionally accurate, leak-proof, and compatible with other standardized systems. It guarantees a secure fit and long-term reliability for designers and contractors.

Industrial-grade quality, built for

your system

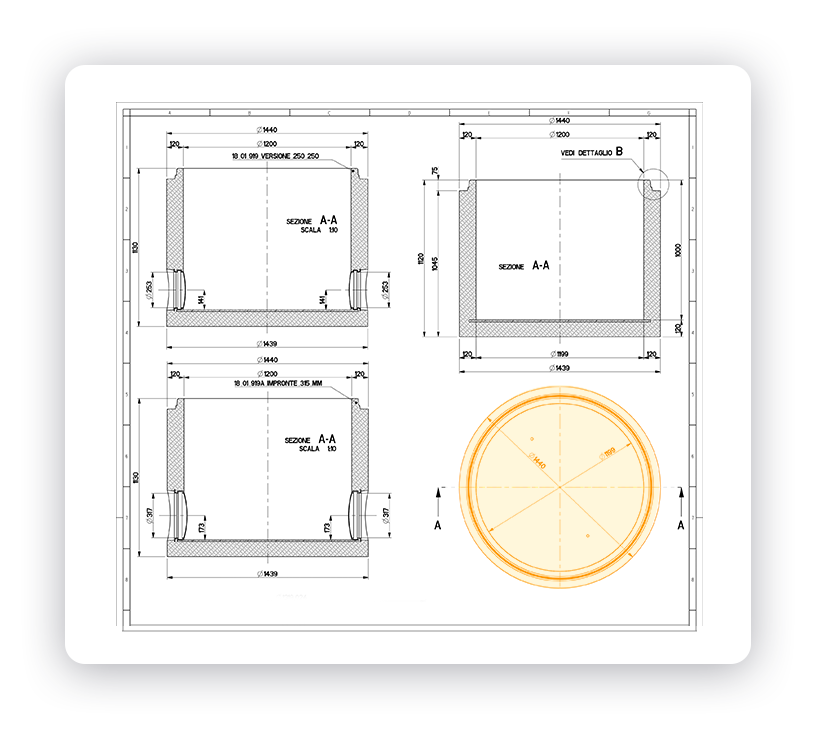

Ferpol’s fitting is a heavy-duty, injection-molded PVC-U

sewer connector, designed primarily for precast

concrete manufacturers and civil engineering

contractors working on stormwater and wastewater

systems.

Every detail is engineered for fast, accurate, and lasting

installation.

The gasket that holds under pressure

A fitting is worthless if it doesn’t seal.

A Ferpol PVC-U idom minden darabjához gyárilag méretezett, minőségi gumigyűrűt adunk.

No need to search, no need to guess. That’s how we ensure a truly watertight, durable, and compliant connection.

Whether it’s a stormwater or wastewater system, leakage is not an option.

Click the button to request a quote with your specifications.

You’ll not only find a general size, but one that fits your system.

Ferpol fittings can be customized to

perfectly fit the customer’s manufacturing equipment. No need for adjustments or modifications.

In general, you can choose from the following lengths and

diameters:

Technical Datasheet

Need exact measurements, materials, or installation details? Check the full

technical datasheet to plan with confidence.

Our certifications you can build on

In technical and construction projects, there’s no room for uncertainty. Our products

are backed by independent certifications to ensure compliance and performance.

NMÉ (National Technical Assessments) Certification

Ferpol PVC-U fittings are products tested and certified by ÉMI (Construction Quality Control Innovation Nonprofit). This means that they are officially approved for use in construction. This certification is also key for public procurement, municipal or state investments.

ISO 9001 – Quality Management

Our entire production process is documented, controlled, and traceable, ensuring

consistent product quality.

+ ISO 14001 – Environmental Management

Our recycling and sustainability practices are not just intentions. They are certified systems that meet international environmental standards.

This is how our products are used in practice:

Frequently Asked Questions

Don’t let issues surface when it’s too late

❌ A weak connection will not fail on the test bench, but on-site, when it is too late.

❌ A missing seal will not cause problems in the warehouse, but when the project slips because of it.

❌ A few millimeters of deviation may seem insignificant at first, but when the production line is at a standstill, it can result in significant losses.All of this could have been prevented if

the supplier had really listened to you.

Not just delivering, but adapting. Not just

manufacturing, but taking responsibility for

their product. This is what sets us apart.

English

English  Magyar

Magyar Română

Română Polski

Polski